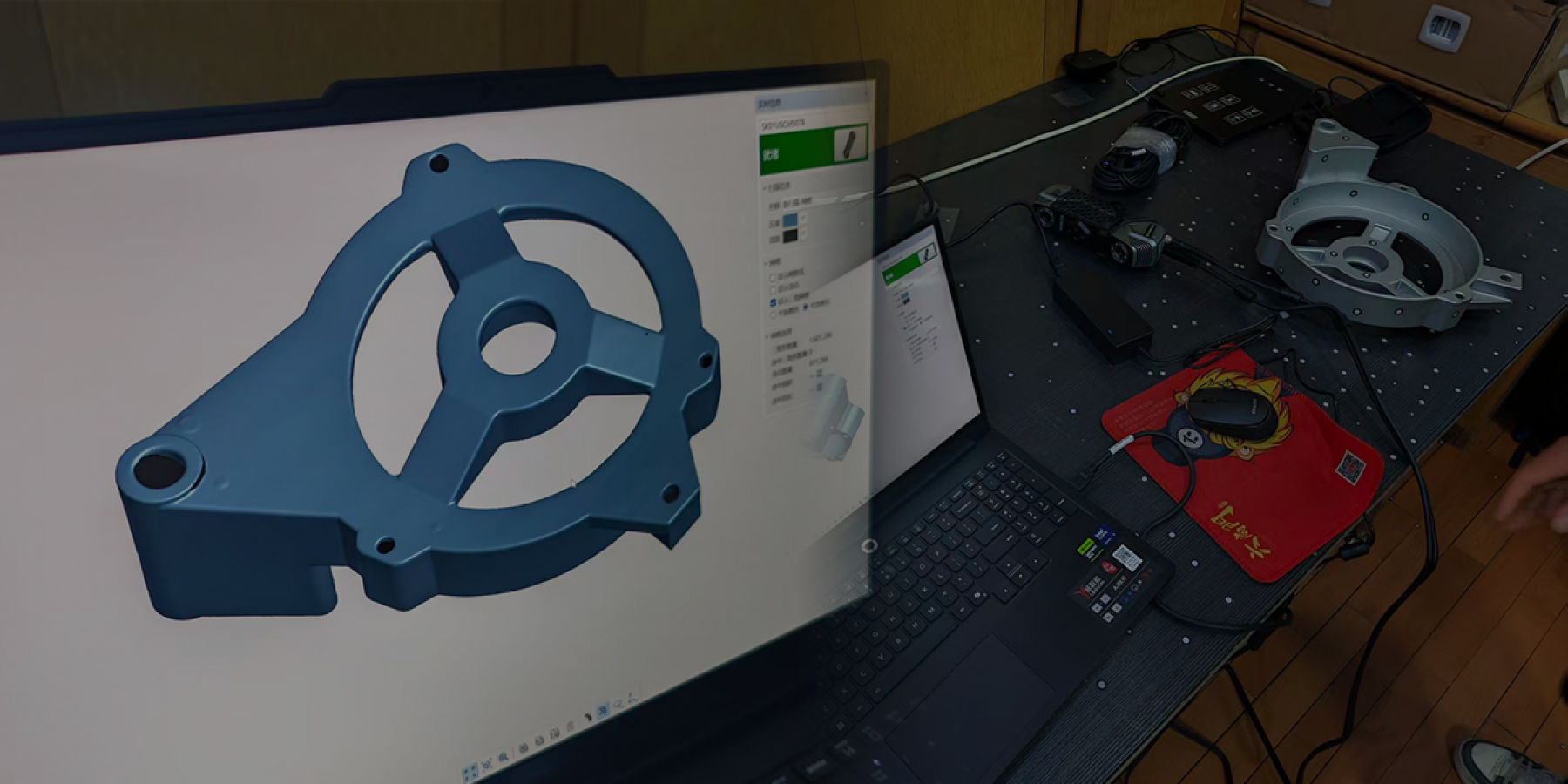

• Sample part scanning

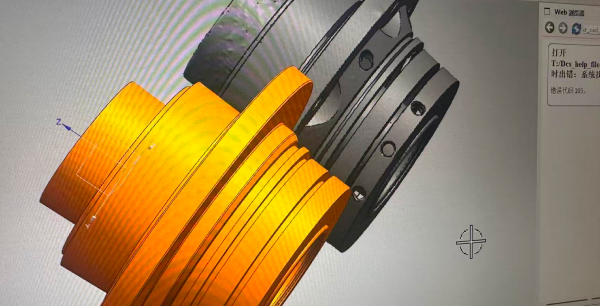

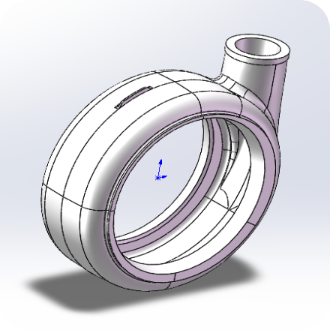

• 3D modeling

• White model production

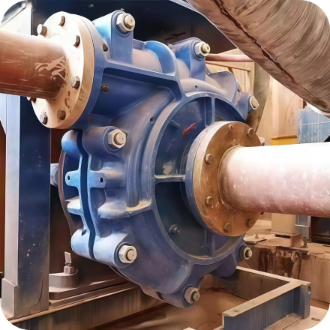

• Accessory casting

• Machining

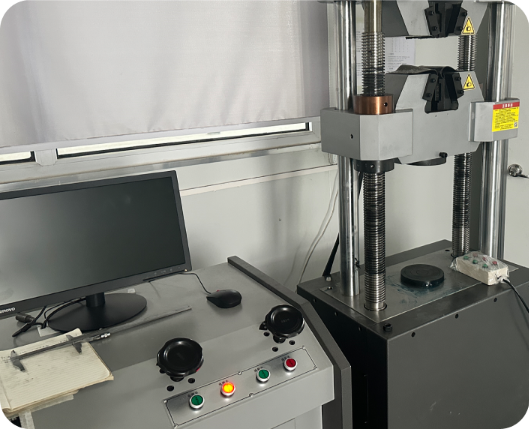

• Inspection

Focusing on OEM customization ofwear-resistant components such as slurry pumps and feed pumps for filter presses.

Roviding one-stop solutions for industriessuch as mining, metallurgy, coal, chemical, and building materials.

Localization of spare parts for oldequipment.

Replacement for importedequipment parts.

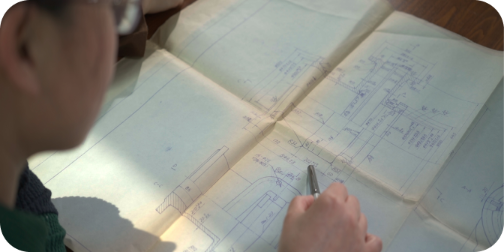

Precise replication of parts withoutdrawings.

Structural upgrades andperformance enhancements afterworking condition optimization.

Demand communication and solution evaluation

• Provide equipment operating conditions (such as medium composition, particle size, concentration, temperature, potential of hydrogen value, head, flow rate, etc.).

• On-site installation space, interface dimensions, and expected service life.

• Assess whether OEM customization is suitable.

• Determine if there is a need to optimize the existing design (such as material upgrades, structural reinforcement, sealing form adjustments, etc.)

White Model Production and Casting Process Design.

Acquisition of accessory samples and 3D casting

Assemble the finished components with the customer's equipment for trial fitting, checking for installation compatibility, coaxiality, sealing effectiveness, and other factors.

If needed, perform bench tests or on-site trial runs to verify performance parameters such as flow rate, head, vibration, noise, and sealing reliability.

Based on the assembly and testing results, make necessary adjustments to the design to ensure it meets the customer's actual operating conditions.

The advantages of OEM processing.

/imported equipment.

OEM PROCESSING

Contact Us

You can contact us in the following four ways. We will communicate with you immediately upon receiving your inquiry!

Call Us

Send Email

Message Form

Add WeChat or WhatsApp