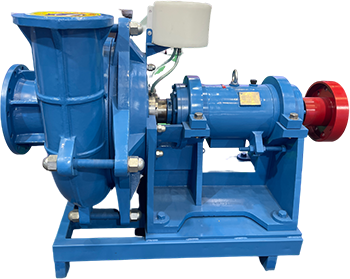

Rubber Liner Slurry Pumps

Corrosion resistance mineral slurry pumps Sunlike Pump ® SHR series rubber liner slurry pumps have the features of replaceable corrosion-resistant rubber liners. They are ideal choice for conveying fine particles and corrosive slurries without sharp edge. A major advantage of the Sunlike slurry pump is multi-optional materials, such as Natural rubber, Nitrile rubber, Polyurethane etc. This enable a pump to be constructed with the most appropriate materials specifically to meet the duty requirements. These wet parts can be mixed use for better performance, lower cost and longer lifetime.

Key word:

Slurry Pumps Gravel Sand Pumps

Products Rubber Slurry Pumps

E-mail:

Products detail

Specification

| CLEAR WATER PERFORMANCE | ||||||

| Model | MAX Power | Capacity | Head | Speed | MAX.Ef | NPSH |

| (kw) | (m3/h) | (m) | (r/min) | n% | (m) | |

| ZMR-10/8E | 120 | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 |

| ZMR-10/8R | 300 | |||||

- SHR-1.5/1B

- SHR-2/1.5B

- SHR-3/2C

- SHR-4/3C

- SHR-4/3D

- SHR-6/4D

- SHR-6/4E

- SHR-8/6E

- SHR-10/8F

- SHR-10/8ST

- SHR-12/10ST

Features

- Adopts a modular design for easy maintenance; high standardization also contributes to lower spare parts costs.

- Offers a wide range of impeller options, including standard 5-vane impellers and open-type 3-vane non-clogging impellers.

- Provides pump liners in 27% chrome alloy hard metal, thick rubber, and polyurethane—all of which are interchangeable with one another.

- Features a standard ductile iron pump body, capable of withstanding higher operating pressures.

- Utilizes bearing components from well-known brands, enhancing reliability, extending bearing service life, and reducing lubrication costs.

- Ensures reliable shaft sealing, with options including packing seals, expeller seals, and mechanical seals.

- Boasts a multi-purpose design that reduces inventory demands while enabling component interchangeability.

- Drive configurations: Multiple motor connection methods (ZVZ, DC, CV, CRZ) are available for selection, meeting the requirements of different installation conditions as well as varying flow rates and heads.

- The pump’s discharge direction can be adjusted to any of 8 positions based on specific installation needs.

Structure Features

A centrifugal heavy - duty rubber - lined corrosion - resistant mineral slurry pump is mainly composed of three parts:

1.The anti - corrosion wet parts: (Impeller, Throatbush, Frame plate liner, Cover plate liner). These wet components are thickened to extend wear life.

2.Shaft seal parts: There is a flexible choice of sealing methods, including gland seal, expeller seal or mechanical seals.

3.Bearing assembly parts

1.The anti - corrosion wet parts: (Impeller, Throatbush, Frame plate liner, Cover plate liner). These wet components are thickened to extend wear life.

2.Shaft seal parts: There is a flexible choice of sealing methods, including gland seal, expeller seal or mechanical seals.

3.Bearing assembly parts

Expeller Seal Assembly: The expeller seal utilizes reversed centrifugal force generated by the impeller to prevent slurry leakage. It is suitable for single-stage pumps where the positive pressure at the pump inlet does not exceed 10% of the outlet pressure, as well as for the first-stage pump in a pump series.

Gland Seal Assembly: The packing seal is a versatile shaft sealing solution applicable to various pumping conditions. Packing made of PTFE or graphite can be used for highly corrosive slurries or high-temperature environments. It features a simple structure and easy maintenance, though it requires shaft seal water with adequate pressure and flow rate.

Gland Seal Assembly: The packing seal is a versatile shaft sealing solution applicable to various pumping conditions. Packing made of PTFE or graphite can be used for highly corrosive slurries or high-temperature environments. It features a simple structure and easy maintenance, though it requires shaft seal water with adequate pressure and flow rate.

Mechanical Seal Assembly: The mechanical seal represents an advanced, leak-free sealing technology. It boasts an integrated design, convenient installation and replacement, and various configurations to accommodate a wide range of operating conditions.

Bearing assembly advantage features:

1.A large - diameter shaft with a short overhang minimizes deflection, which is conducive to prolonging the bearing's service life.

2.Four through bolts are required to secure the cartridge - type housing within the frame.

3.The removable cartridge - type bearing assembly facilitates straightforward on - site maintenance procedures.

4.It is outfitted with a hardened shaft sleeve to safeguard the shaft.

5.Grease - purged piston rings assist in sealing contaminants out of the bearing housing.

2.Four through bolts are required to secure the cartridge - type housing within the frame.

3.The removable cartridge - type bearing assembly facilitates straightforward on - site maintenance procedures.

4.It is outfitted with a hardened shaft sleeve to safeguard the shaft.

5.Grease - purged piston rings assist in sealing contaminants out of the bearing housing.

| Pump Mainly Parts & Material List | |||||

|

NO |

Part |

Material |

NO |

Part |

Material |

|

1 |

Shaft |

High tense steel |

12 |

Volute |

27% Chrome alloy |

|

- |

Shaft sleeve |

3Cr13 |

13 |

Discharge joint ring |

Natural rubber |

|

2 |

Clamp bolts |

Zinc plated steel |

14 |

Volute liner seal |

Natural rubber |

|

3 |

Base |

Ductile iron |

15 |

Intake joint ring |

Natural rubber |

|

4 |

bolts,studs |

Zinc plated steel |

16 |

Expeller |

27% Chrome alloy |

|

- |

Bearing body |

Cast iron |

17 |

Frame plate liner insert |

27% Chrome alloy |

|

5 |

Gland/Split gland |

Cast iron |

18 |

Throatbush |

27% Chrome alloy |

|

6 |

Frame plate |

Ductile iron |

19 |

Cover plate |

Ductile iron |

|

7 |

Expeller ring |

27% Chrome alloy |

20 |

Cotter |

Cast iron |

|

8 |

Expeller ring seal |

Natural rubber |

- |

End cover |

Color zinc plated |

|

9 |

Volute liner seal |

Natural rubber |

- |

Labyrinth cover |

Color zinc plated |

|

10 |

Impeller |

27% Chrome alloy |

- |

Lantern ring |

1Cr18Ni9Ti |

|

11 |

Cover plate bolt |

Zinc plated steel |

- |

Bearing |

Top brand |

Applications

The SH centrifugal heavy - duty alloy - lined mine tailing slurry pump is designed for handling highly abrasive and dense slurries in mineral processing operations. These operations span from cyclone feeding and regrinding to mill discharge, flotation, mine drainage, and tailing. Additionally, it can also be utilized in tasks such as dredging settling lagoons and pumping drilling mud in other industrial scenarios.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

why choose me?

Independent Casting・Traceable Source

Sunlike Pumps is a leading Chinese brand specializing in slurry pumps and filter press feed pumps. All products are manufactured through the company’s own casting and production lines, ensuring complete quality control from the source.

Dual-Plant Synergy・Solid Strength

Sunlike operates two manufacturing campuses: one located in Xingtang Industrial Park, Shijiazhuang, Hebei Province, and the other in Anzhou Industrial Park, Xiong’an New Area, Baoding, Hebei Province, with a total area of 50,000 square meters.

Trusted by Top Brands・Partner with Strength

Sunlike pumps are long-term supporting equipment for well-known Chinese filter press manufacturers such as Jingjin, Dazhang, and Bright. The company is also a trusted partner of major industrial enterprises including BYD and Haiwang Hydrocyclone.

Service Advantage

As a company specializing in the production of slurry pumps, sewage pumps, filter press feed pumps and environmentally friendly greening equipment, SUNLIKE meets the diverse needs of customers.

One year warranty for the whole machine

Advanced equipment and technology

Timely supply from overseas warehouses

24-hour online problem solving

Common Problem

1. What is the main use of slurry pump?

Slurry pump is mainly used to transport liquid containing solid particles, widely used in mining, metallurgy, coal, electric power, chemical, building materials and environmental protection and other industries.

2. What is the working principle of the slurry pump?

The slurry pump inhales the slurry from the suction inlet of the pump body through the centrifugal force generated by the rotation of the impeller, and the slurry is discharged from the discharge outlet of the pump body through the diversion of the pump shell.

3. How to choose the right slurry pump?

The selection of slurry pump needs to consider the following factors:

The physical and chemical properties of the medium, such as temperature, viscosity, corrosion, etc

The size and concentration of solid particles

Required flow and head

Pump material and structure

4. What are the precautions for the maintenance and maintenance of slurry pump?

Check the wear condition of impeller, pump housing and shaft seal regularly, and replace the worn parts in time

Keep pump body and pipe clean to prevent impurities from entering pump body

Check and replace lubricating oil regularly to ensure the normal operation of bearings

Check the coupling of the motor and pump regularly to ensure that the connection is secure

5. What are the common faults and treatment methods of slurry pump?

The pump does not produce pulp or insufficient pulp: check whether the suction inlet is blocked, whether there is air in the pump body, and whether the impeller is worn.

Pump body vibration or noise: check whether the pump shaft is bent, the impeller is balanced, and the bearing is damaged.

Seal failure, leakage: check whether the seal wear, replace the seal in time.

{{ item2.relationTitle }}

{{ item2.relationIntroduce }}

1

2

Contact Us

You can contact us in the following four ways. We will communicate with you immediately upon receiving your inquiry!

Call Us

Send Email

Message Form

Add WeChat or WhatsApp